ARTICLE

15 Questions About Using Helical Piles for Pipeline Foundations

Helical piles, also known as screw piles, offer a rapid, reliable, and cost-effective solution for pipeline foundations across Australia’s diverse and often challenging terrain.

This article provides Australian engineers with direct answers to 15 critical questions, covering everything from geotechnical considerations and load capacity verification to corrosion protection and compliance with Australian Standards.

By understanding the technical advantages and installation efficiencies, you can confidently specify helical piles for your next pipeline infrastructure project, ensuring stability, longevity, and minimal environmental impact, even in the most remote locations.

Summary

- Rapid Installation: Helical piles can be installed quickly with minimal site preparation, ideal for remote pipeline projects.

- Immediate Loading: Foundations are ready for immediate loading, eliminating concrete curing times and accelerating project schedules.

- Verifiable Capacity: Installation torque directly correlates to the pile’s load capacity, providing real-time quality assurance on site.

- All-Weather Work: Installation is possible in various weather conditions, reducing costly project delays.

- Minimal Impact: The process involves no excavation spoils and minimal ground disturbance, protecting sensitive environments.

- Versatility: Helical piles are suitable for a wide range of Australian soil conditions, from reactive clays to sandy soils.

1. How Do Helical Piles Function as Pipeline Foundations?

Helical piles function as a deep foundation system, transferring a pipeline’s structural loads to deeper, more competent soil. They are steel shafts with one or more helical plates welded to them, resembling a large screw. During installation, the pile is screwed into the ground using a hydraulic drive motor.

As it advances, the helical plates move through the soil with minimal disturbance. Once the required depth and installation torque are reached, the pile is securely anchored in a stable load-bearing stratum. This provides a solid base for pipeline support structures, resisting compressive, uplift, and lateral forces.

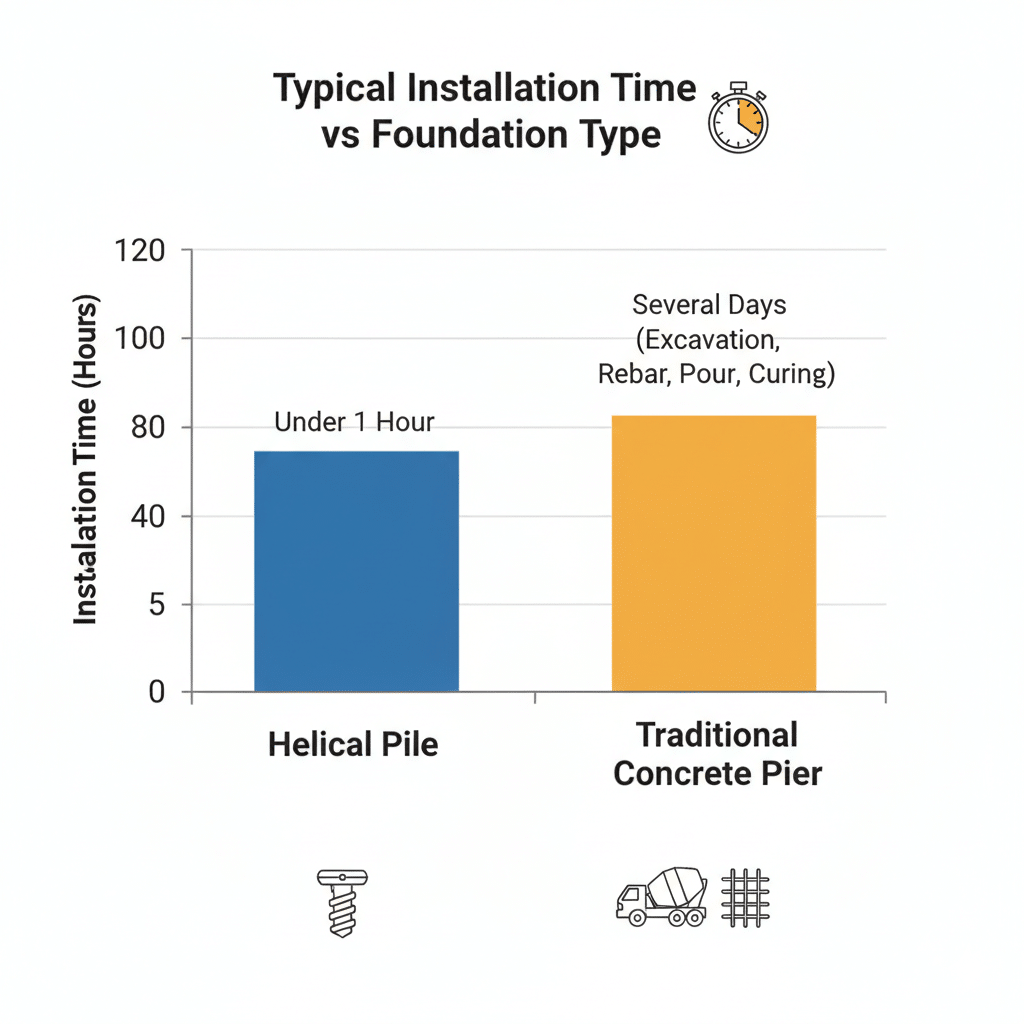

2. What Are the Main Advantages Over Traditional Concrete Foundations?

For pipeline projects, especially in remote Australian locations, helical piles offer significant advantages over traditional bored concrete piers. The primary benefits revolve around speed, logistics, and quality assurance. Unlike concrete, helical piles require no excavation, formwork, or curing time.

They can be loaded immediately after installation, which drastically shortens construction schedules. The equipment used is also smaller and more mobile, simplifying access to challenging sites and reducing the overall environmental footprint.

Data Table: Helical Piles vs. Traditional Concrete Piers

| Feature | Helical Piles | Traditional Concrete Piers |

|---|---|---|

| Installation Speed | Fast (minutes per pile) | Slow (days for excavation, pouring, curing) |

| Site Disturbance | Minimal, no spoils | Major excavation, spoil removal required |

| Equipment | Smaller machinery (e.g., excavator with drive head) | Large drill rigs, concrete trucks, pumps |

| Curing Time | None, immediate loading | 7-28 days required |

| Weather Dependency | Low | High (rain can halt concrete pours) |

| Quality Assurance | Real-time torque monitoring | Relies on concrete testing after the fact |

| Remote Access | Excellent | Logistically complex and expensive |

| Environmental Impact | Low noise, low vibration, low carbon footprint | High noise, vibration, high carbon footprint |

3. How Is the Load Capacity of a Helical Pile Determined and Verified?

The ultimate load capacity of a helical pile is verified during installation through a well-established engineering principle: the torque-to-capacity relationship. As the pile is screwed into the ground, the resistance encountered from the soil is measured as rotational torque. This installation torque is directly proportional to the bearing capacity of the pile.

The relationship is expressed by the formula:

Ultimate Capacity = Kt x T

Where ‘T’ is the final installation torque and ‘Kt’ is an empirical torque factor specific to the pile’s shaft diameter. This method allows engineers to verify the capacity of every single pile in real-time, providing an exceptional level of quality assurance.

4. What Geotechnical Information Is Required for Helical Pile Design?

A thorough geotechnical investigation is essential for the proper design of any helical pile foundation. The report provides the critical data needed to select the appropriate pile configuration, including shaft diameter, helix size and arrangement, and target installation depth.

Key information required includes soil stratigraphy (the sequence of soil layers), soil classification and properties (e.g., density, plasticity), shear strength parameters, and Standard Penetration Test (SPT) results.

For long-term durability, data on soil pH, resistivity, and chloride or sulphate content is also needed to assess potential corrosion and design the required protection.

5. Can Helical Piles Be Used in All Australian Soil Conditions?

Helical piles are remarkably versatile and suitable for a vast range of Australian soil conditions. They perform exceptionally well in reactive clays, silts, sands, and even in areas with a high water table. The design can be customised by changing the helix size and spacing to optimise performance in specific soil types.

Their main limitation is in ground that is obstructed by solid rock, dense gravel, or a high concentration of large boulders, which can prevent the pile from advancing to its target depth. In some cases of difficult ground, a pre-drilled pilot hole can help overcome minor obstructions.

6. How Do Helical Piles Handle Pipeline Buoyancy and Uplift Forces?

In flood-prone areas or locations with high groundwater levels, pipelines are subject to significant buoyancy forces that can cause them to lift out of the ground. Helical piles are an excellent solution for pipeline buoyancy control. The helical plates act like anchors, providing substantial resistance to uplift (tensile) forces.

When the pile is screwed into competent soil, the soil above the helices creates a large cone of resistance, effectively holding the pipeline down. The pile’s capacity in tension is often comparable to its capacity in compression, making it a reliable and engineered method for anchoring infrastructure against uplift.

7. What Is the Design Life and Approach to Corrosion Protection?

The design life of a steel helical pile is a direct function of its corrosion protection system and the aggressiveness of the surrounding soil conditions. For critical infrastructure like pipelines, a long service life is mandatory.

The standard method of protection in Australia is hot-dip galvanizing, which applies a thick, sacrificial zinc coating to the steel. The thickness of this coating can be specified to meet a design life of 50 to 100+ years, depending on the soil’s properties.

In highly aggressive soils, additional measures like epoxy coatings or cathodic protection systems can be implemented.

Data Table: Corrosion Protection Options Based on Soil Aggressiveness

| Soil Condition | Typical Protection Method | Estimated Service Life (Years) |

|---|---|---|

| Non-Aggressive (Low moisture, neutral pH) | Standard Galvanized Steel | 75+ |

| Mildly Aggressive (Moderate moisture, low salts) | Heavy-Duty Galvanized Steel | 50-75 |

| Aggressive (High moisture, high salinity/acidity) | HD Galvanized Steel + Epoxy Coating / Cathodic Protection | 50-100+ |

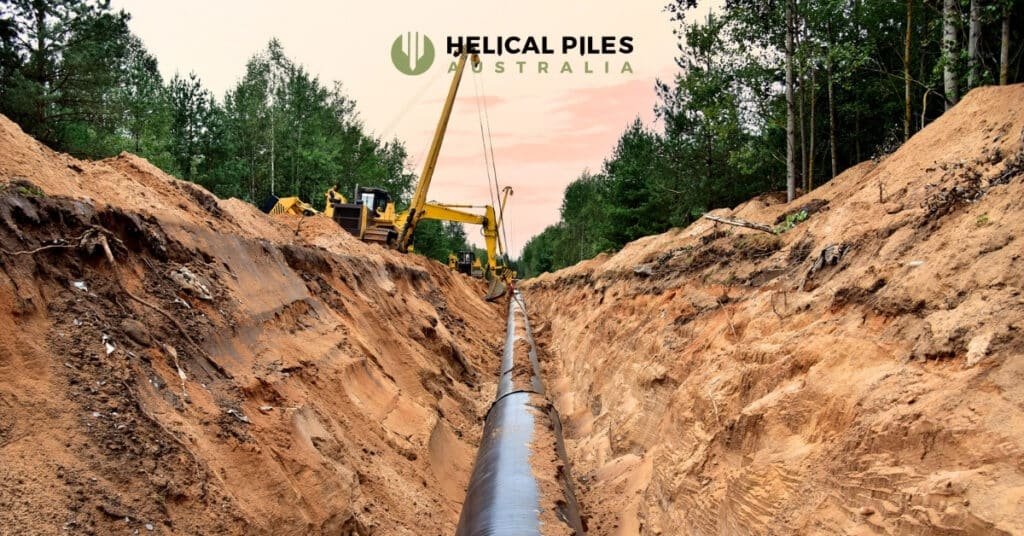

8. How Does Installation Work in Remote or Limited-Access Areas?

Helical pile installation is uniquely suited for remote and difficult-to-access sites common in Australian pipeline projects. The required machinery—typically an excavator or large skid steer with a hydraulic drive head—is smaller and more manoeuvrable than the large drill rigs needed for concrete piles.

This equipment can be more easily transported to isolated locations. The process does not require water for mixing concrete or heavy logistics for spoil removal, simplifying site operations and significantly reducing the costs associated with establishing a construction presence in remote areas.

9. What Australian Standards Govern Helical Pile Design and Installation?

The design, installation, and testing of helical piles in Australia are governed by the national standard AS 2159-2009 Piling – Design and installation. This comprehensive standard provides Australian engineers with the framework for ensuring foundation systems are safe, reliable, and fit for purpose.

It covers aspects such as load capacity calculations, material specifications, durability considerations, and on-site testing and verification procedures. Adherence to AS 2159 is essential for any reputable piling contractor and provides asset owners with confidence in the foundation’s long-term performance.

10. What Impact Does Installation Have on the Surrounding Environment?

The environmental impact of helical pile installation is minimal, which is a key advantage for projects crossing sensitive landscapes like agricultural land or native bush. The installation process is virtually vibration-free, making it safe to use near existing structures or in environmentally sensitive zones.

Because the pile displaces the soil rather than excavating it, no spoils are brought to the surface. This eliminates the need for spoil transportation and disposal, preserving the site’s original condition and reducing the overall carbon footprint of the project.

11. Are Helical Piles a Cost-Effective Solution for Pipeline Projects?

When considering the total project cost, helical piles are a highly cost-effective solution for pipeline foundations. While the material cost of a single pile may be comparable to the materials for a concrete pier, the savings in labour, time, and equipment are substantial.

The rapid installation process significantly shortens the overall construction schedule, reducing labour costs and overheads. Eliminating the need for concrete trucks, water supply, and spoil removal further brings down expenses, particularly on remote projects where logistical costs are high.

12. How Do Helical Piles Perform in Areas with Seismic Activity?

Helical piles demonstrate excellent performance under seismic loading conditions. As a deep foundation system made from ductile steel, they can flex and move with the ground during a seismic event without a sudden, brittle failure.

The design can be engineered specifically to meet the seismic requirements outlined in Australian Standard AS 1170.4, ensuring the foundation can withstand the lateral and vertical forces associated with earthquakes in a specific region. The helical plates also provide strong anchorage, helping to resist soil liquefaction effects.

13. Can Helical Piles Be Used for Temporary Pipeline Supports?

Yes, helical piles are an ideal choice for temporary pipeline supports, such as those needed for bypass lines during maintenance or repair work. Because they are screwed into the ground, they can just as easily be screwed out and removed once they are no longer needed.

This allows for complete removal of the foundation system, leaving minimal trace and allowing the site to be fully remediated. The removed piles can often be reused on future projects, adding to their cost-effectiveness and sustainability.

14. What Equipment is Needed for Helical Pile Installation?

The equipment required for helical pile installation is relatively standard and readily available across Australia. The core components are:

- Primary Machine: An excavator, skid steer loader, or backhoe with sufficient hydraulic capacity to generate the required torque.

- Hydraulic Drive Head: A high-torque motor that attaches to the primary machine and rotates the pile into the ground.

- Torque Monitoring Device: A digital, in-line gauge that provides the operator with a real-time readout of the installation torque, ensuring quality control for every pile.

- Extensions and Tools: Drive pins, kelly bar adapters, and extensions as needed to reach the target pile depth.

15. How Are Piles Connected to the Pipeline Support Structures?

Helical piles are terminated with a variety of connection interfaces to suit different pipeline support designs. The most common connection is a flat steel plate cap that is welded to the top of the pile shaft. This plate can be pre-drilled to allow for the bolting of a pipeline sleeper, cradle, or stanchion.

Other options include threaded rods for adjustable connections or custom-fabricated brackets designed to integrate directly with specific pipeline support hardware. This versatility ensures a simple, strong, and efficient transfer of loads from the pipeline to the foundation.

On Using Helical Piles for Pipeline Foundations

For Australian engineers tasked with delivering robust and efficient pipeline infrastructure, helical piles present a compelling alternative to conventional foundations. Their rapid, verifiable, and low-impact installation process addresses the key logistical and environmental challenges of working across Australia.

By leveraging the benefits of immediate loading, adaptability to diverse soil conditions, and inherent cost-effectiveness, helical piles offer a technically superior and commercially advantageous solution for modern pipeline support systems. This technology ensures long-term stability while compressing project timelines.

Frequently Asked Questions About Helical Piles for Pipeline Foundations

What Are the Disadvantages of Helical Piles?

The primary limitations of helical piles are their unsuitability for solid rock or ground with a high density of boulders and cobbles, which can cause the pile to deflect and fail to advance. They may also have depth limitations depending on the equipment used, and their capacity can be sensitive to improper installation techniques, making it vital to use experienced contractors.

How Long Do Helical Piles Last?

The service life of a helical pile is dependent on the corrosion protection system and the aggressiveness of the soil conditions. A standard hot-dip galvanized steel pile installed in a non-aggressive soil environment can easily achieve a design life of 75 years or more, meeting the long-term requirements for critical infrastructure like pipelines.

What Is the Load Capacity of a Helical Pile?

The load capacity is highly variable and depends on the pile’s configuration (shaft diameter, helix size and number) and the properties of the soil it is installed in. Capacities can range from a few tonnes for small-diameter piles to over 100 tonnes for large, multi-helix piles installed in dense soil strata. Capacity is determined on a project-specific basis by a geotechnical engineer.

When Should You Not Use Helical Piles?

You should not use helical piles when the subsurface is composed of solid bedrock or contains a high concentration of large obstructions like boulders. Additionally, they may not be the most economical choice for very shallow foundation requirements where a simple concrete slab-on-ground would suffice, or for extremely heavy, concentrated loads that would require an impractically large number of piles.

What Are Helical Piles Used For?

Beyond pipeline foundations, helical piles are widely used for a variety of applications, including supporting residential and commercial buildings, solar panel arrays, communication towers, bridges, and retaining walls. They are particularly useful for foundation underpinning and repair work due to the low-vibration installation process.

How Are Helical Piles Installed?

Helical piles are installed using a hydraulic drive head attached to machinery like an excavator. The pile is screwed into the ground in a continuous, smooth motion. The operator monitors the installation torque in real-time. The pile is advanced until it reaches the predetermined design depth and/or the required torque value is achieved, indicating it has reached competent, load-bearing soil.

Need a quote or more info? Start here.

Contact Us

info@helicalpilesaustralia.com.au

+61 2 7251 9258

Mon–Fri, 8:00am–5:00pm AEST

Built for complexity.

Engineered for certainty.

A trusted partner for large-scale energy and infrastructure projects where precision isn’t optional, it’s mandatory

© 2025 Helical Piles Australia. All rights reserved.

Privacy Policy

Contact Us

info@helicalpilesaustralia.com.au

+61 2 7251 9258

Mon – Fri, 8:00am – 5:00pm AEST

Location

Ground Floor 3, 189 Kent St

Sydney, NSW 2000