ARTICLE

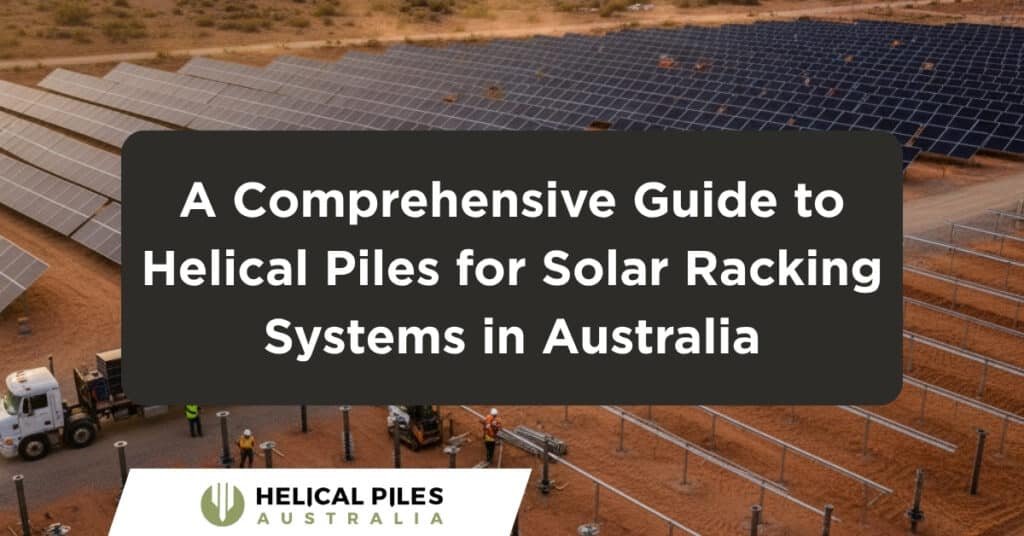

Helical Piles for Solar Racking Systems

Summary

- Helical piles offer a rapid, low-impact, and adaptable foundation solution for ground-mounted solar racking systems.

- They are particularly advantageous in Australia’s varied and often challenging soil conditions, from reactive clays to remote, sandy sites.

- Proper geotechnical investigation and adherence to Australian Standards (e.g., AS 2159, AS/NZS 1170.2) are paramount for successful project outcomes.

- This system provides significant time and cost savings compared to traditional concrete footings, especially for large-scale solar farms.

- This article covers the technical specifications, design considerations, and installation processes relevant to Australian engineers.

Helical piles, often referred to as screw piles, are a type of deep foundation system that uses a central steel shaft with one or more helix-shaped plates to transfer loads into the ground. In the context of renewable energy, they have become a leading foundation choice for ground mount solar racking.

This engineered solution is installed by rotating it into the ground with hydraulic machinery, avoiding the need for extensive excavation or concrete. For Australian solar farms, particularly large utility-scale projects, helical piles offer an efficient, reliable, and adaptable alternative to traditional foundations.

Table: Foundation System Comparison for Utility-Scale Solar

| Feature | Helical Piles | Concrete Piers/Ballasts | Ground Screws |

|---|---|---|---|

| Installation Speed | High (Up to 150+ per day) | Low (Requires excavation & curing) | High |

| Site Disturbance | Minimal | High | Minimal |

| Soil Suitability | Wide range (clays, sands, rock) | Requires stable, excavatable soil | Good in soil, struggles in rock |

| Adjustability | High (easily extended/adjusted) | Low (permanent) | Moderate |

| Carbon Footprint | Low (recyclable steel, no cement) | High (cement production) | Low |

| Remote Access | Excellent (smaller machinery) | Poor (requires concrete trucks) | Excellent |

| Load Capacity | High (torque-correlated) | High (design dependent) | Moderate to High |

| Cost-Effectiveness | High (reduced labour & time) | Moderate (material cost + labour) | High (reduced labour & time) |

Technical Advantages of Helical Piles for Solar Installations

Immediate Load-Bearing Capacity

A key advantage is the ability to load the foundation immediately after installation. This accelerates the construction schedule by allowing solar racking and panels to be mounted without waiting for a concrete curing period, which is a significant commercial advantage for large-scale solar farm construction.

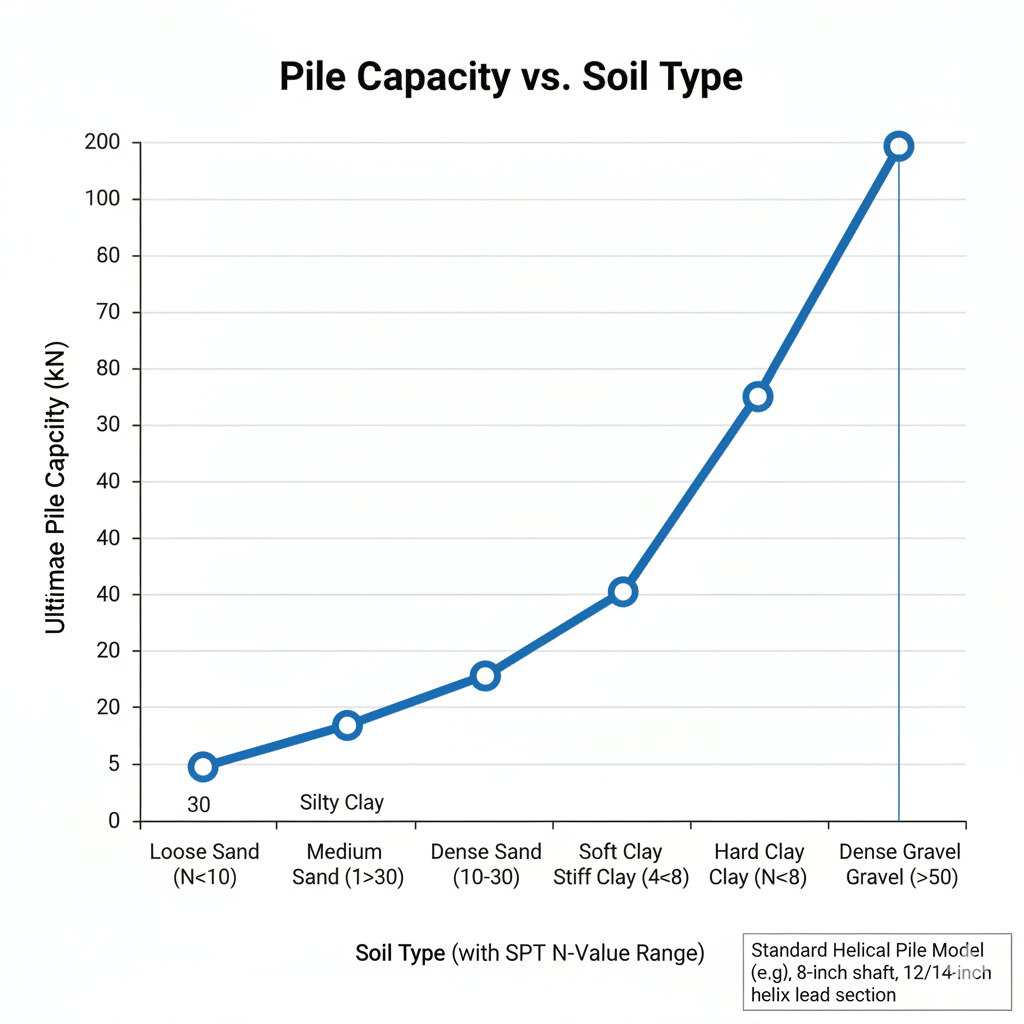

High Performance in Diverse Australian Geology

Helical piles can be engineered to succeed in Australia’s varied soil conditions, from the expansive clays of Victoria and Queensland to the sandy profiles of Western Australia. By adjusting the pile diameter, length, and helix configuration, the foundation is designed to bypass weaker surface soils and achieve the required uplift and compression capacity in a competent underlying stratum.

Verifiable Capacity via Torque Correlation

The installation process itself serves as a quality assurance metric. The torque required to advance the pile into the ground correlates directly to its load-bearing capacity. This real-time data provides engineers with immediate, on-site verification that the pile meets its design requirements, making this method of pile load testing both efficient and highly reliable.

Minimal Environmental Impact

The installation creates minimal soil displacement and ground vibration, preserving the site’s natural state. At the end of a solar farm’s life, the piles can be easily unscrewed from the ground, leaving a minimal footprint. The steel is also fully recyclable, contributing to a more sustainable decommissioning process.

Design and Engineering Considerations for Australian Conditions

Designing a helical pier solar panel foundation in Australia requires adherence to established national standards and careful consideration of local environmental factors.

The primary guiding document is AS 2159-2009 (Piling – Design and Installation), which outlines the requirements for designing and installing piled foundations. Engineers must use this standard to determine the ultimate geotechnical and structural strength of the piles.

Wind loading is the most significant structural force acting on a ground-mounted solar array. Consequently, compliance with AS/NZS 1170.2 (Wind Actions) is essential. The foundation design must be robust enough to resist the calculated uplift and shear forces specific to the project’s wind region in Australia.

Given the typical 25 to 30-year design life of a solar project, corrosion protection for steel piles is a non-negotiable design input. For most Australian environments, hot-dip galvanizing provides sufficient protection.

However, for sites with aggressive soil conditions (e.g., low pH, high salinity) or near coastal areas, a more detailed corrosion assessment is needed. This may lead to specifying a thicker galvanized coating or the inclusion of sacrificial anodes to ensure long-term durability.

The design must also accommodate the specific helical pile solar racking details, ensuring the connection between the top of the pile and the racking system is engineered to transfer all loads effectively.

Geotechnical Investigation and Site Suitability

A comprehensive geotechnical investigation is the cornerstone of a successful helical pile foundation design.

It is not an optional step; it is an essential precursor to engineering the foundation system. The report provides the critical data needed to understand the subsurface conditions and inform the design of a pile that is both safe and cost-effective.

Information required from the geotechnical report includes the soil profile detailing the different layers, the engineering properties and classification of those soils (e.g., clay, sand, silt), groundwater levels, and the depth to bedrock or any obstructions.

This data allows engineers to determine the most suitable bearing stratum and calculate the required embedment depth.

This information directly influences the helical pile foundation design. For instance, a site with soft surface soils will require a longer pile to reach a deeper, more competent layer.

The helix configuration, the number, diameter, and spacing of the helical plates, is selected based on the soil properties to optimise both uplift and compression resistance. For sites with known rock, specialised lead sections or pre-drilling techniques may be specified.

Table: Geotechnical Data & Helical Pile Design Implications

| Geotechnical Finding | Implication for Helical Pile Design |

|---|---|

| Soft/Loose Upper Strata | Requires deeper embedment to reach a competent bearing layer. May need shaft extension. |

| Highly Reactive Clays | Helices must be founded below the zone of seasonal moisture change to prevent uplift. |

| Presence of Rock/Cobbles | May require pre-drilling or selection of a specialised rock-cutting lead section. |

| High Water Table | Requires assessment of potential buoyancy and specification of appropriate corrosion protection. |

| Corrosive Soil (Low pH) | Mandates higher-grade galvanization or other sacrificial anode systems for design life. |

Summary On Helical Piles for Solar Racking

For Australian engineers designing ground-mounted solar projects, helical piles present a technically superior, efficient, and reliable foundation system.

Their rapid, low-impact installation minimises project timelines and site disturbance, offering significant advantages over traditional concrete.

The ability to adapt the pile design to Australia’s highly variable ground conditions, from reactive clays to remote sandy sites, ensures a robust solution. Verified in real-time through torque monitoring, helical piles provide a high degree of engineering certainty.

They represent a smart, modern solution that aligns perfectly with the demands of the fast-growing renewable energy sector.

Frequently Asked Questions About Helical Piles for Solar Racking

How Do You Anchor a Solar Panel to the Ground?

For ground-mounted systems, solar panels are attached to a metal solar racking frame. This frame is then anchored to the ground using a foundation system designed to resist all environmental loads, especially wind uplift. Helical piles serve as a popular and effective foundation, acting as deep anchors that are screwed into the ground to provide a stable and secure base for the racking.

Can You Put Solar Panels on a Pier?

Yes, and this is exactly what a helical pile functions as. A “pier” is a type of foundation that transfers loads to deeper, more competent soil. A helical pile is an engineered steel foundation pier. It is an ideal solution for supporting solar arrays because it can be installed quickly and its capacity can be verified, making it a reliable deep foundation for solar panel ground mount footings.

What Is the Best Foundation for Ground Mounted Solar Panels?

The “best” foundation is entirely dependent on project-specific variables, including the site’s geotechnical conditions, accessibility, project schedule, and budget. While concrete footings have been used traditionally, helical piles are often considered the optimal choice for projects where speed of installation, minimal site disturbance, and performance in variable or poor soils are high priorities, which is common for large-scale solar farms.

What Are the Disadvantages of Helical Piles?

The primary limitation of helical piles is their performance in ground with high concentrations of large cobbles, boulders, or shallow, solid bedrock. While specialised techniques can overcome some of these challenges, such conditions can slow installation or require a different foundation approach in those specific areas. The initial material cost per pile can also appear higher than the raw materials for concrete, but this is typically offset by significant savings in labour, machinery time, and accelerated project schedules.

How Far Apart Should Ground Mounted Solar Panels Be?

The spacing between rows of ground-mounted solar panels is determined by the array’s design, not the foundation type. Key factors include the tilt angle of the panels and the geographic location, which dictate the necessary distance to prevent one row from casting a shadow on the row behind it (known as inter-row shading). The helical pile layout is then engineered to match the support points specified by the solar racking manufacturer to achieve this design.

How Deep Do Helical Piles Need to Be for Solar Panels?

There is no standard depth. The required depth for a helical pile is an engineered outcome, not a predetermined number. It is calculated based on two main factors: the loads from the solar array (especially wind uplift) and the soil conditions identified in the geotechnical report. The pile is installed until its helices are embedded in a soil layer strong enough to provide the required load capacity, which is verified by achieving a target installation torque. This depth could be as shallow as 1.5 metres or exceed 5 metres in very weak soils.

Need a quote or more info? Start here.

Contact Us

info@helicalpilesaustralia.com.au

+61 2 7251 9258

Mon–Fri, 8:00am–5:00pm AEST

Built for complexity.

Engineered for certainty.

A trusted partner for large-scale energy and infrastructure projects where precision isn’t optional, it’s mandatory

© 2025 Helical Piles Australia. All rights reserved.

Privacy Policy

Contact Us

info@helicalpilesaustralia.com.au

+61 2 7251 9258

Mon – Fri, 8:00am – 5:00pm AEST

Location

Ground Floor 3, 189 Kent St

Sydney, NSW 2000