ARTICLE

Corrosion Protection for Helical Piles in Australian Coastal Environments

Building along Australia’s stunning coastline comes with a unique set of challenges, chief among them being the aggressive nature of the environment towards building materials. Steel, the core component of helical piles, is particularly vulnerable if not adequately protected.

The combination of salt, water, and oxygen creates the perfect recipe for corrosion, which can compromise the structural integrity of a foundation over time. Understanding these specific local factors is the first step in engineering a foundation that will stand the test of time.

The Impact of High Salinity and Chloride Levels

Properties anywhere from the Gold Coast to Perth’s coastal suburbs are constantly exposed to salt-laden air and sea spray. This salt doesn’t just sit on the surface; it permeates the ground, creating highly saline soil and groundwater.

When steel is exposed to this environment, the high concentration of chloride ions actively breaks down the natural, passive protective layer on the steel’s surface.

This process significantly accelerates the rate of rusting and metal loss, far beyond what would be experienced in an inland, drier climate.

This is why a standard, unprotected steel pile is simply not a viable long-term option for coastal foundation solutions in Australia.

Soil Composition and Corrosivity Factors

The type of soil itself plays a major role in how quickly corrosion occurs. Australian coastal areas feature a wide range of soil types, from the loose sandy soil of beachside locations to the more reactive clays found slightly further inland.

A professional geotechnical investigation is essential to understand the specific properties of the soil at your site. Key factors that determine a soil’s corrosivity include its resistivity (a measure of how easily an electrical current can pass through it, lower resistivity means higher corrosion potential), its pH level, and its moisture content.

This data allows engineers to classify the site’s corrosivity and design an appropriate protection strategy.

The Splash Zone and Atmospheric Corrosion

For any part of a helical pile that is exposed above ground, such as in sub-floor applications or on steeply sloped blocks, atmospheric corrosion becomes a major concern.

The area just above the ground or in the inter-tidal “splash zone” is often the most aggressively corrosive environment. It experiences constant cycles of wetting and drying with salt-rich water, combined with high oxygen availability. This creates a corrosion rate that can be many times higher than for the section of the pile buried deep in the soil.

Therefore, the protection system must account for both the below-ground and above-ground conditions the pile will face throughout its service life.

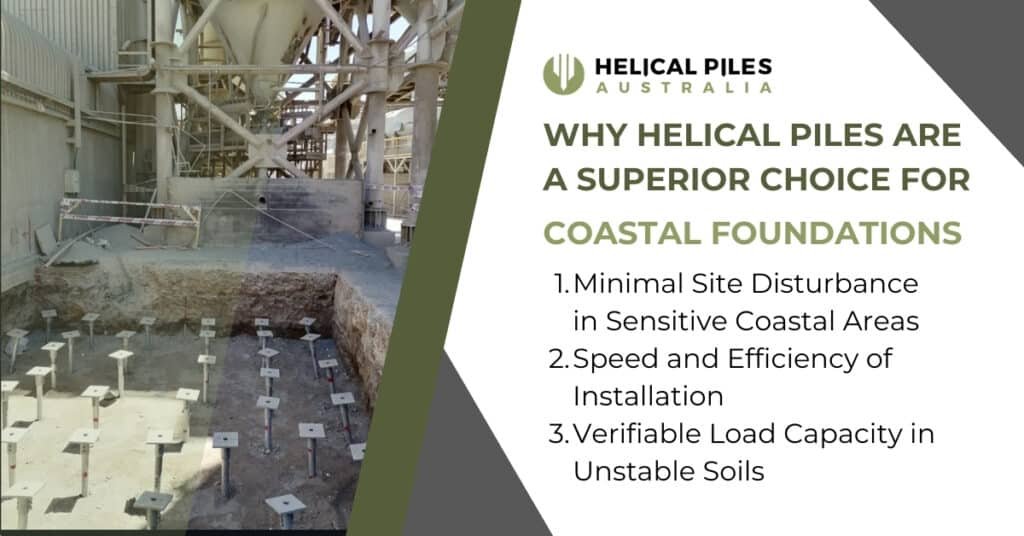

Why Helical Piles are a Superior Choice for Coastal Foundations

Given the harsh conditions, selecting the right foundation system is paramount. Helical piles, also commonly known as screw piles, offer distinct advantages that make them particularly well-suited for Australian coastal construction and remediation projects.

Their unique design and installation method address many of the common problems encountered when building on the variable and often unstable ground found near the coast.

Minimal Site Disturbance in Sensitive Coastal Areas

Many Australian coastal regions are environmentally sensitive, with delicate dune systems and native vegetation. Traditional foundation methods, such as driving concrete piles or excavating for strip footings, can cause significant disruption to the site.

The installation of helical piles is a low-impact alternative. The piles are screwed into the ground with hydraulic-powered machinery, resulting in minimal soil displacement and vibration. This preserves the site’s natural landscape and is often a preferred method for councils in ecologically sensitive areas.

Speed and Efficiency of Installation

Coastal weather can be unpredictable, and tidal movements can limit the available working hours on foreshore sites. The speed of helical pier installation is a significant advantage. A typical residential foundation can often be installed in a matter of days, not weeks.

There is no need to wait for concrete to cure, so construction of the building can commence almost immediately after the piles are installed. This efficiency helps keep projects on schedule and reduces labour costs.

Verifiable Load Capacity in Unstable Soils

One of the greatest challenges of building on sandy soil is confirming the foundation’s load-bearing capacity. Helical piles provide a unique solution to this problem. During installation, the hydraulic pressure, or torque, required to screw the pile into the ground is continuously monitored.

This installation torque has a direct, engineered correlation to the pile’s ultimate load-bearing capacity. This means that every single pile is load-tested as it’s installed, providing a verifiable guarantee of performance and peace of mind for builders and homeowners alike.

Primary Methods for Helical Pile Corrosion Protection

To ensure helical piles achieve their intended design life in corrosive coastal environments, a robust protection system is essential. There isn’t a one-size-fits-all solution; the choice of protection depends on the severity of the site conditions identified in the geotechnical report. Several proven methods are used across Australia to provide effective, long-term corrosion protection for helical piles.

Hot-Dip Galvanization: The Industry Standard

The most common and cost-effective method for protecting helical piles is hot-dip galvanization. This process involves immersing the fabricated steel pile in a bath of molten zinc. This creates a series of zinc-iron alloy layers that are metallurgically bonded to the steel, with a final outer layer of pure zinc. This coating, specified under Australian Standard AS/NZS 4680, provides protection in two ways.

First, it acts as a durable barrier, sealing the steel from the corrosive environment. Second, it provides cathodic protection; if the coating is scratched, the surrounding zinc will corrode preferentially (or “sacrifice” itself) to protect the exposed steel. The thickness of the galvanised helical piles’ coating is a key factor in determining its lifespan.

High-Build Epoxy Coatings: An Added Layer of Defence

For particularly aggressive environments where galvanization alone may not be sufficient to achieve a long design life, a high-build epoxy coating for screw piles can be applied over the top of the galvanized steel. This dual-coating system offers a superior level of protection. The epoxy forms a thick, inert barrier that is highly resistant to abrasion during installation and provides excellent protection against both chlorides and other chemicals in the soil. This approach is often specified for critical infrastructure projects or high-value properties in the most severe coastal settings.

The Premium Option: Stainless Steel Helical Piles

For the ultimate in corrosion resistance, stainless steel helical piles are the premium choice. While the initial material cost is higher, they can offer the lowest whole-of-life cost in extremely corrosive environments where other systems might require future maintenance or replacement.

Marine-grade stainless steel, such as grade 316, contains elements that create a highly resilient passive film on the surface, allowing it to withstand severe chloride exposure without significant corrosion. This option is typically reserved for projects demanding a very long design life (100+ years) in the most aggressive marine conditions.

Cathodic Protection Using Sacrificial Anodes

Cathodic protection is a sophisticated electrochemical method used to control corrosion on buried or submerged steel. In the context of helical piles, this usually involves attaching a sacrificial anode to the pile shaft. This anode is made from a more reactive metal, typically zinc or magnesium.

When the pile and anode are buried in the soil (the electrolyte), a galvanic cell is created. The more reactive anode corrodes preferentially, effectively turning the steel pile into the cathode and preventing it from rusting. The size and composition of the sacrificial anode are engineered to provide a specific level of protection for a predetermined period, helping to achieve the required design life.

The Role of Soil Analysis in Determining Protection Levels

You cannot effectively manage what you do not measure. This is particularly true for foundation design in coastal Australia. Simply guessing the level of corrosion protection required is a recipe for premature failure or unnecessary expense.

A professional, data-driven approach is essential, and this begins with a comprehensive analysis of the soil at the specific building site.

Why a Geotechnical Investigation is Non-Negotiable

Before any foundation design or installation begins, a geotechnical investigation conducted by a qualified engineer is a critical first step. This investigation involves drilling boreholes, collecting soil samples, and analysing them in a laboratory.

The resulting geotechnical report provides the blueprint for the entire foundation system. It identifies the different soil layers, determines their strength and stability, and, crucially, assesses their corrosivity. Attempting to design a foundation without this information is working blind.

Key Metrics to Test For

During the soil testing phase, several key metrics are analysed to build a complete picture of the site’s corrosive potential. These include:

- Soil Resistivity: This measures how easily an electrical current (the driver of the corrosion cell) can flow through the soil. Low resistivity values indicate a more corrosive environment.

- pH Levels: This indicates the acidity or alkalinity of the soil. Highly acidic or alkaline soils can accelerate the breakdown of protective coatings.

- Chloride and Sulphate Content: The concentration of these aggressive ions is measured. High chloride levels, typical in coastal areas, are a primary cause of accelerated steel corrosion.

- Moisture Content: The presence of water is necessary for the corrosion process to occur. Soils that retain a high level of moisture are generally more corrosive.

Matching the Protection System to the Site

The data gathered from the soil analysis allows engineers to make an informed decision about the most appropriate and cost-effective corrosion protection for helical piles. A site with moderate corrosivity might only require a standard hot-dip galvanized pile to achieve a 50-year design life.

However, a site with very low soil resistivity and high chloride content might necessitate a dual system of galvanization plus an epoxy coating, or the addition of sacrificial anodes, to meet the same 50-year or a longer 100-year requirement. This tailored approach ensures the foundation is neither under-engineered nor over-engineered, providing safety and value.

Designing for Longevity: Design Life and Australian Standards

A foundation is not a temporary structure; it is intended to support a building for its entire lifespan. Therefore, the concept of “design life” is fundamental to the engineering process.

It involves making deliberate choices about materials and protection systems to ensure the foundation performs safely for a specified period without requiring unplanned, major repairs.

What is “Design Life”?

In foundation engineering, “design life” refers to the period for which a structure is expected to perform its intended function. For typical residential homes in Australia, the required design life is often 50 years, as stipulated in the National Construction Code.

For commercial buildings or critical public infrastructure, this can extend to 100 years or more. When designing a helical pile foundation, the engineer must select a corrosion protection system that ensures the pile retains its required structural strength for the full duration of this specified design life.

Adherence to Australian Standard AS 2159

Professionalism and safety in the Australian piling industry are guided by a set of rigorous standards. Australian Standard AS 2159 – “Piling – Design and installation” is the primary document governing this work. This standard provides detailed guidance on how to assess soil corrosivity from geotechnical data and how to calculate potential steel loss over time.

It then outlines the requirements for protective coatings and other measures needed to counteract this loss and achieve the target design life. Adhering strictly to AS 2159 ensures that the foundation design is compliant, safe, and based on sound engineering principles.

Calculating Corrosion Loss Over Time

Based on the soil analysis and the tables within AS 2159, an engineer can estimate the rate of corrosion for both unprotected and galvanized steel at a particular site. For example, the standard might help determine that in a specific soil, a galvanized coating will lose zinc at a rate of 15 micrometres per year.

By knowing the initial coating thickness (e.g., 600 grams/m²), the engineer can calculate how long the coating will last and ensure this meets or exceeds the building’s required design life. This calculated approach removes guesswork and provides a solid basis for specifying the right level of protection.

Installation Practices for Preserving Pile Coatings

The best corrosion protection system in the world can be rendered ineffective if it is damaged during handling or installation. The expertise of the installation crew is just as important as the quality of the materials.

Professional installers follow strict protocols to ensure the protective coatings on helical piles remain intact, providing a continuous barrier against the corrosive soil environment.

The Importance of Careful Handling

Protection begins before the pile even enters the ground. Coated helical piles must be stored on-site in a way that prevents them from being scraped or damaged, for example, by storing them on wooden blocks rather than directly on the ground.

They must be loaded, unloaded, and moved around the site with care, using appropriate slings and equipment to avoid impacts that could chip or compromise the galvanized or epoxy coating.

Using the Right Equipment

During installation, using the correct equipment is vital. The hydraulic drive head that grips and turns the pile must be the correct size and type to avoid damaging the pile shaft. More importantly, the installer must carefully monitor the installation torque.

Over-torquing the pile can place excessive stress on the steel and can cause abrasion damage to the coating as it is driven through dense or rocky soil layers. A skilled operator knows how to “feel” the ground conditions and adjust the installation parameters to ensure a smooth and damage-free process.

Touch-ups and Repairs

Despite the best care, minor scuffs and scratches can sometimes occur during the installation of helical piles. A professional installation protocol includes a final inspection of the pile after it has been installed to its final depth.

Any minor damage found on the exposed section of the pile is meticulously cleaned and repaired using an approved, zinc-rich cold galvanizing spray or an epoxy touch-up paint. This ensures the integrity of the protective barrier is maintained, leaving no weak points for corrosion to attack.

Summary On Corrosion Protection for Helical Piles

Protecting your coastal Australian property starts from the ground up. The corrosive nature of our coastal soils makes a robust foundation system not just a recommendation, but a necessity for long-term structural integrity. Helical piles, when combined with a professionally specified and installed corrosion protection system, offer a superior solution.

By investing in a data-driven approach that includes thorough geotechnical analysis and adherence to Australian Standards, you can ensure your foundation is engineered to last. This foresight protects your building and provides peace of mind for decades to come.

Frequently Asked Questions About Corrosion Protection for Helical Piles

How Long Do Helical Piles Last in the Ground?

The lifespan of a helical pile depends entirely on the corrosivity of the soil and the level of corrosion protection applied. A properly engineered helical pile in a non-aggressive soil can last well over 100 years. In the aggressive coastal soils found across Australia, a standard galvanised helical pile might have a design life of 25-50 years, while advanced systems with dual coatings or cathodic protection can be designed to last 100 years or more, meeting the requirements of any residential or commercial structure.

Do Helical Piles Rust?

Yes, because they are made from steel, unprotected helical piles will rust. However, the goal of a professional foundation design is not to prevent rust entirely, but to control the rate of corrosion so that it is insignificant over the building’s design life. This is achieved through proven protection methods like hot-dip galvanization, which creates a durable protective barrier that slows the corrosion process to a highly predictable and manageable rate.

How Do You Protect Piles From Corrosion?

There are several highly effective methods used to protect helical piles in Australia. The most common methods include applying a thick zinc coating via hot-dip galvanization, adding a secondary protective layer with a high-build epoxy coating, using sacrificial anodes to provide cathodic protection, or for maximum defence, manufacturing the piles from high-grade stainless steel. The most appropriate method for a project is always determined by a site-specific soil analysis.

What Is the Life Expectancy of a Steel Pile?

The life expectancy of a steel pile is not a fixed number; it is an engineered outcome. Based on geotechnical data and the guidelines in Australian Standard AS 2159, engineers can design a specific protection system for a steel pile to achieve a target design life. Whether the requirement is 50 years for a coastal home or over 100 years for critical public infrastructure, the protection system can be tailored to meet that specific engineering requirement.

Are Screw Piles Suitable for Sandy Soil?

Absolutely. Screw piles, which is another industry term for helical piles, are an excellent foundation solution for the sandy soil commonly found along the Australian coastline. The helical plates are specifically designed to engage with and derive high load capacity from granular soils like sand. Furthermore, the screw-in installation method is ideal for sand as it causes minimal disturbance and compaction issues.

How Deep Should Helical Piles Be in Coastal Areas?

The required depth for a helical pile is never a predetermined number; it is dictated by the findings of a geotechnical investigation. The piles must be installed deep enough to bypass any upper layers of loose, unstable sand or soil and anchor firmly into a competent, load-bearing stratum below. A geotechnical engineer will specify the target depth and the required installation torque for each pile on the project to guarantee the foundation’s stability and load capacity.

Need a quote or more info? Start here.

Contact Us

info@helicalpilesaustralia.com.au

+61 2 7251 9258

Mon–Fri, 8:00am–5:00pm AEST

Built for complexity.

Engineered for certainty.

A trusted partner for large-scale energy and infrastructure projects where precision isn’t optional, it’s mandatory

© 2026 Helical Piles Australia. All rights reserved.

Privacy Policy

Contact Us

info@helicalpilesaustralia.com.au

+61 2 7251 9258

Mon – Fri, 8:00am – 5:00pm AEST

Location

Ground Floor 3, 189 Kent St

Sydney, NSW 2000