ARTICLE

Design Guide to Helical Pile Foundations for Solar Farms in Australia

Summary

- Overview: This guide details the design and installation of helical pile foundations for Australian solar farms. It provides engineers with a framework for designing robust and efficient foundation systems for ground-mounted solar arrays.

- Key Focus: We cover critical aspects such as geotechnical investigation, load analysis (compression, uplift, lateral), pile selection, and adherence to Australian Standards (AS 2159).

- Advantages: Helical piles offer rapid installation, minimal site disturbance, and immediate load-bearing capacity, making them an ideal solution for Australia’s diverse and often challenging ground conditions.

- Design Process: Successful solar foundation design hinges on accurate soil data, correct torque-to-capacity correlation, and appropriate corrosion protection strategies tailored to local environmental factors.

- Audience: This resource is specifically created for geotechnical, structural, and civil engineers across Australia seeking a technical, data-driven approach to solar foundation design.

Why Helical Piles are an Optimal Choice for Australian Solar Farms

The selection of a foundation system has a significant impact on the timeline, budget, and environmental footprint of a solar farm project. Helical piles present a compelling case for Australian conditions for several key reasons.

Their installation speed is a primary advantage; unlike traditional concrete foundations that require excavation, formwork, and curing time, helical piles can be installed and loaded immediately. This can shave weeks or even months off a project schedule.

Furthermore, the installation process involves minimal site disturbance. The piles are screwed directly into the earth, which means there is no soil excavation or spoil removal required. This preserves topsoil, reduces the risk of erosion, and minimises the overall environmental impact of construction, a critical consideration for projects in sensitive or agricultural areas.

This method is also ideal for the remote and logistically challenging locations where many Australian solar farms are situated. Finally, helical piles demonstrate excellent performance across the continent’s diverse soil conditions, from the reactive clays of Victoria and New South Wales to the sandy soils of Western Australia.

Navigating Australian Standards and Compliance

For any engineering work in Australia, adherence to national standards is paramount to ensure safety, quality, and durability. The following table outlines the key documents and guidelines relevant to the design and installation of helical pile foundations for solar projects.

| Standard / Guideline | Role | Key Provisions and Scope |

|---|---|---|

| AS 2159-2009 Piling – Design and installation | Primary Governing Standard | Provides a comprehensive framework covering geotechnical investigation, design actions, installation procedures, and load testing protocols. Compliance is fundamental for structural integrity. |

| Clean Energy Council (CEC) Guidelines | Industry Best Practice | Outlines best practices for solar farm construction, including foundation selection and installation. While not a legislative document, it provides valuable industry-specific context. |

| National Construction Code (NCC) & Local Council Requirements | Supplementary Regulations | May contain provisions that influence foundation design, particularly relating to site-specific conditions, zoning, and local environmental regulations. |

The Foundation of Design: Geotechnical Investigation

A successful helical pile solar foundation design begins long before any calculations are made. It starts with a comprehensive, site-specific geotechnical investigation. This investigation is the most critical phase of the design process, as it provides the essential data needed to understand how the soil will interact with the piles.

A detailed geotechnical report for a solar farm should provide a clear picture of the subsurface profile, including soil classification, stratigraphy, shear strength parameters (cohesion and friction angle), groundwater levels, and a soil corrosivity assessment.

This data is not optional; it directly informs every aspect of the pile design. It determines the required pile embedment depth, the necessary helix configuration (diameter and number of plates), and the anticipated installation torque required to achieve the design load capacity. Attempting a design without robust geotechnical data introduces unacceptable levels of risk into the project.

Core Design Principles for Helical Pile Solar Foundations

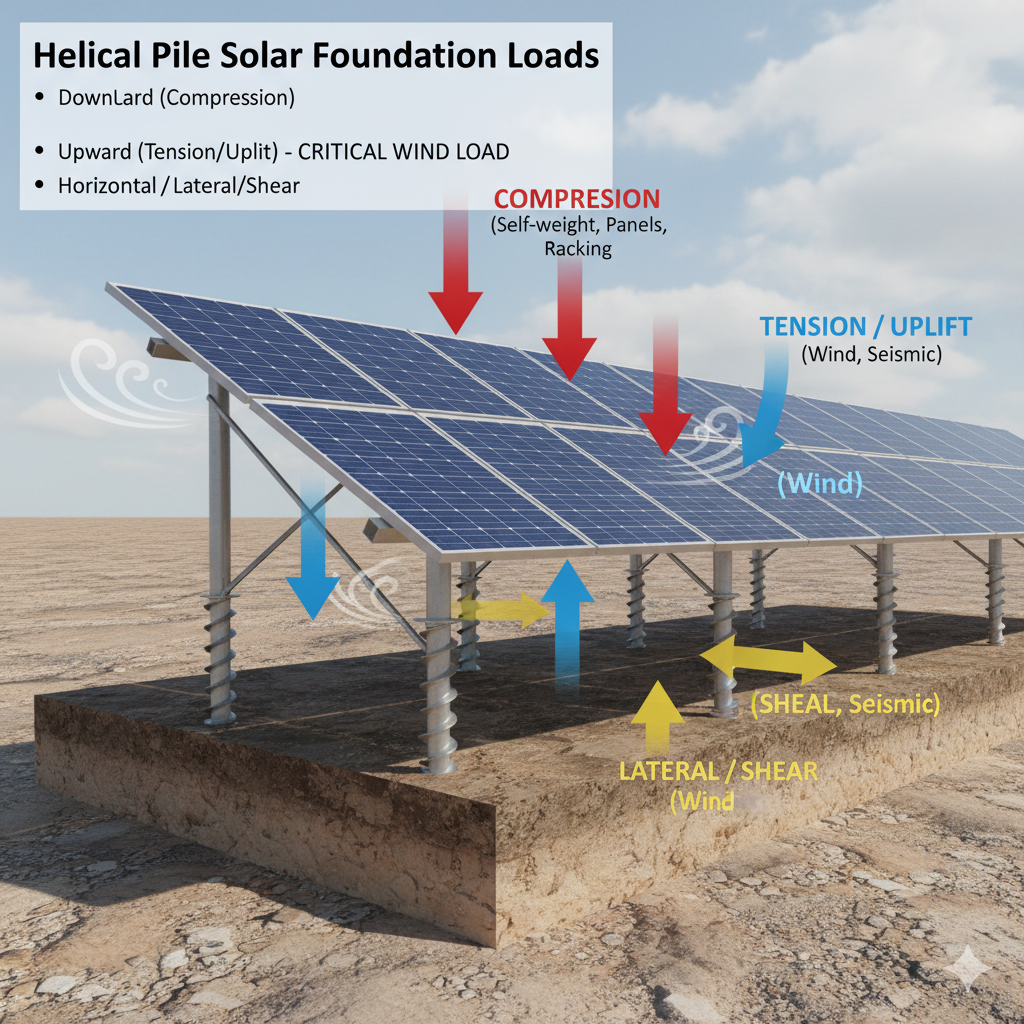

Understanding Solar Array Loads

The design of a helical pile foundation must account for all the forces that will act upon it throughout its service life. For a solar array, these loads are complex and multi-directional. They are broadly categorised as downward (compression), upward (tension or uplift), and horizontal (lateral or shear) loads.

Downward loads include the self-weight of the solar panels, the steel racking system, and the helical pile itself. While important, these are often not the governing loads. The most critical force in Australian solar foundation design is typically the uplift load generated by wind.

The large surface area of solar panels acts like a sail, and strong winds can create immense tensile forces that try to pull the foundation out of the ground. Lateral loads are also generated by wind and, in some regions, seismic activity, pushing horizontally against the array.

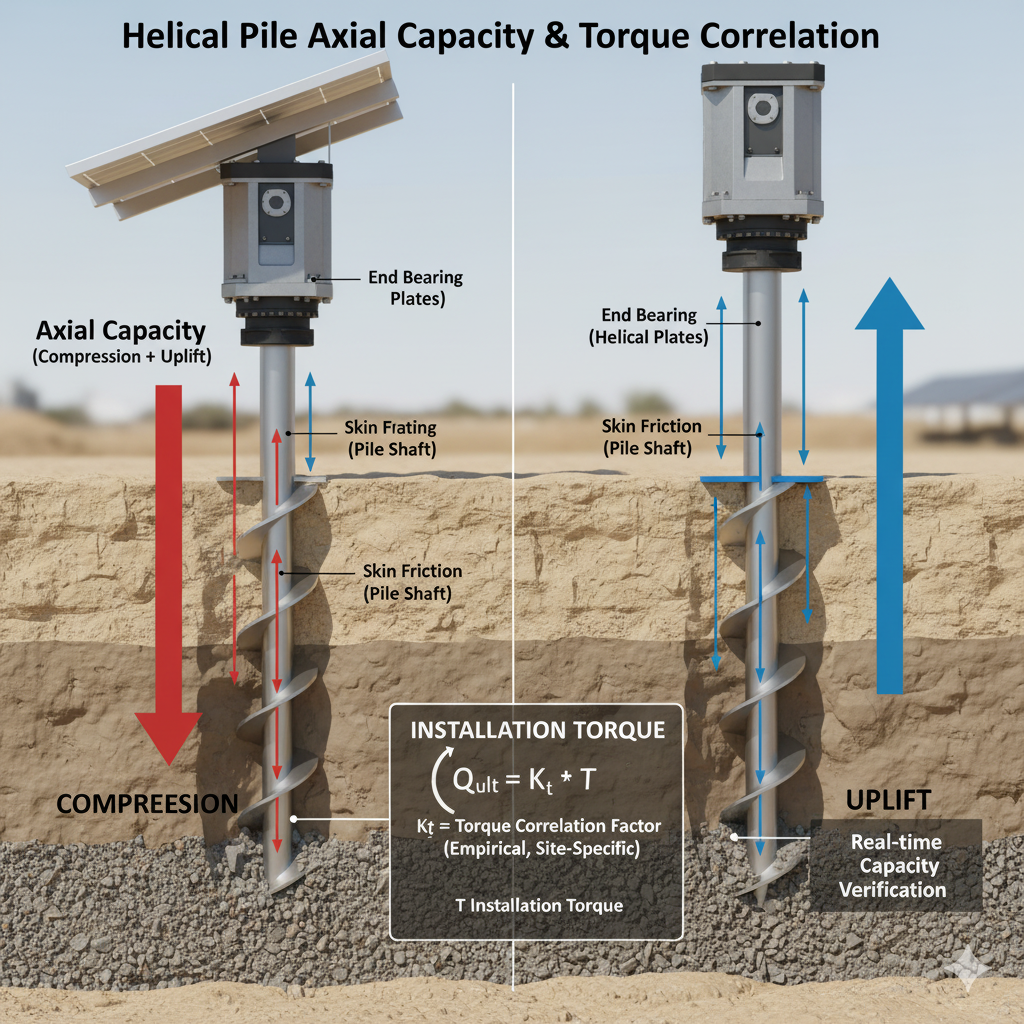

Axial Capacity (Compression and Uplift)

Axial capacity refers to the pile’s ability to resist both compression and uplift forces along its vertical axis. The total capacity is derived from the sum of two components: the end-bearing capacity of the helical plates and the skin friction along the pile shaft.

The design can be approached using two primary methods. The first is a theoretical approach using bearing capacity equations found in AS 2159, which relies on the shear strength parameters of the soil from the geotechnical report.

The second, and more commonly used, method is torque correlation. This is an empirical method that relates the amount of rotational energy (torque) required to install the pile to its ultimate axial capacity.

This relationship is one of the most significant advantages of helical piles, as it allows for the capacity of every single pile to be verified in real-time during installation. The general formula is:

Kt is the torque correlation factor, which is an empirical coefficient that depends on the geometry of the pile shaft. This factor must be determined through site-specific load testing to be validated for a project.

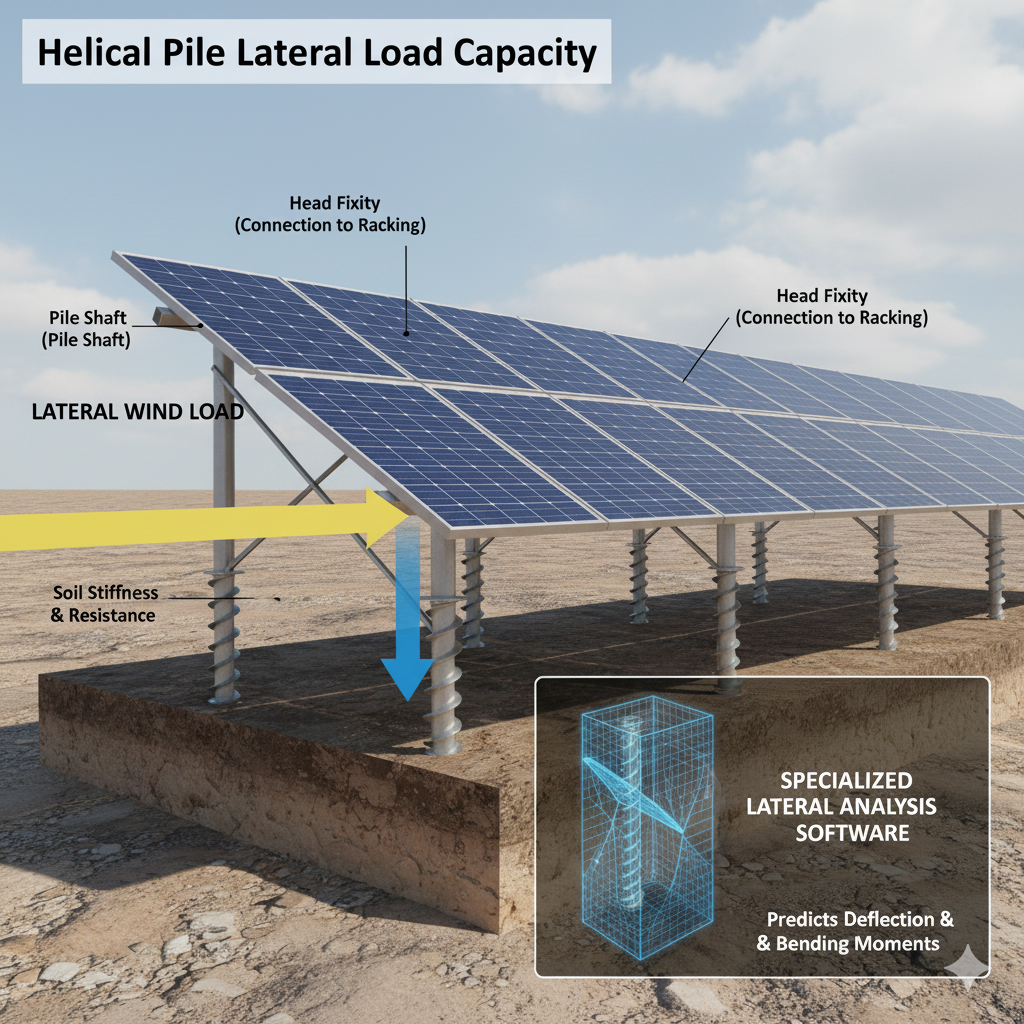

Lateral Load Capacity

The ability of a helical pile foundation to resist horizontal forces is crucial for the stability of the entire solar array. Lateral capacity is influenced by the stiffness of the soil, the diameter and bending stiffness of the pile shaft, and the way the pile is connected to the racking system at its head (head fixity).

For large-scale solar farms where wind loads are significant, a detailed lateral analysis is often required. This is typically performed using specialised software that models the pile-soil interaction to predict deflection and bending moments under the design lateral loads.

Installation and Quality Assurance

The Installation Process

The installation of helical piles is a streamlined and efficient process carried out with standard construction equipment, such as an excavator or a large skid steer, fitted with a high-torque hydraulic drive head. The process follows a clear sequence:

- First, the site is surveyed, and the precise location for each pile is marked out according to the solar array design.

- The installation equipment is then positioned over the marked location.

- The helical pile is attached to the drive head and screwed into the ground at a consistent speed and with sufficient downward pressure, known as “crowd,” to ensure it advances smoothly.

- If required, extension shafts are added to achieve the design depth or until the target installation torque is reached.

- Finally, once the pile is at its final depth, it is cut to the required height, and the connection bracket for the solar racking is fitted.

The Role of Torque Monitoring

Torque monitoring is the cornerstone of quality assurance for helical pile installation. During installation, a calibrated digital torque measurement device is used to record the torque applied to the pile continuously. This provides a real-time, in-situ assessment of the pile’s load-bearing capacity.

By correlating the final installation torque with the predetermined torque-to-capacity relationship (Qu = *Kt*T), the engineer can verify that every pile installed meets or exceeds the required design capacity. This provides a level of quality control that is difficult to achieve with other foundation systems.

(Image: Example graph showing installation torque increasing with pile depth until the design torque is met.)

Load Testing Protocols

To validate the design assumptions and, most importantly, the project-specific torque correlation factor (Kt), on-site load testing is performed before the main production installation begins.

These tests, conducted in accordance with AS 2159, typically involve applying tension, compression, and lateral loads to sacrificial test piles and measuring their deflection.

The results of these tests confirm that the selected pile design will perform as expected in the specific site conditions, providing the project stakeholders with the highest level of confidence in the foundation system.

Helical Piles vs. Other Solar Foundation Systems

While helical piles offer many advantages, it is important for engineers to understand how they compare to other common solar foundation systems used in Australia.

| Feature | Helical Piles | Ground Screws | Concrete Ballasts/Piers |

|---|---|---|---|

| Installation Speed | Very Fast | Fast | Slow |

| Site Disturbance | Minimal | Low | High |

| Soil Suitability | Wide Range | Good in soil, poor in rock | Adaptable but requires extensive excavation |

| Carbon Footprint | Low | Low | High |

| Removability | Easy | Easy | Difficult & Costly |

| Cost (Material) | Moderate | Moderate | Low |

| Cost (Labour/Plant) | Low | Low | High |

| QA Method | Real-time Torque Monitoring | Real-time Torque Monitoring | Concrete slump/strength tests |

Wrapping Up: On Helical Pile Solar Foundation Design

The design of helical pile foundations for solar farms in Australia is a systematic process grounded in sound engineering principles. It successfully combines a thorough understanding of geotechnical conditions with a precise analysis of structural loads.

The system’s advantages, including rapid installation and verifiable on-site quality assurance through torque monitoring, make it a highly competitive choice. When designed and installed in accordance with Australian Standards, helical piles provide a reliable, durable, and cost-effective foundation solution.

This enables the efficient rollout of renewable energy infrastructure across the country.

Frequently Asked Questions About Helical Pile Solar Foundations

How Do You Design a Helical Pile Foundation?

A helical pile foundation is designed through a multi-stage process. It begins with a detailed geotechnical investigation to understand the soil properties. Next, the structural loads from the solar array, including compression, uplift from wind, and lateral forces, are calculated. Based on this data, an appropriate pile size, shaft, and helix configuration is selected. Finally, the required installation torque is specified to ensure the pile achieves its required load capacity, which is then verified during installation.

What Is the Load Capacity of a Helical Pile?

The load capacity of a helical pile is not a fixed value; it is entirely project-specific. It is determined by two main factors: the soil conditions at the site and the geometry of the pile itself (shaft diameter, and the number and size of the helices). The ultimate capacity is calculated by an engineer and then verified for every pile during installation using the torque correlation method and confirmed with on-site load testing as per AS 2159.

What Are the Disadvantages of Helical Piles?

While highly versatile, helical piles do have some limitations. They can be difficult to install in ground with dense cobbles, boulders, or solid rock, where they may meet refusal. In such conditions, pre-drilling or an alternative foundation type may be necessary. The initial material cost can also be higher than that of a simple concrete footing, though this is often offset by significant savings in labour, machinery time, and project schedule.

How Are Solar Panel Foundations Installed?

Helical pile foundations for solar panels are installed using standard construction equipment like an excavator or skid steer equipped with a hydraulic high-torque drive head. The pile is simply screwed into the ground to the design depth or until the specified installation torque is achieved. The process is fast, generates minimal noise and vibration, and requires no excavation or spoil removal.

What Foundations Are Used for Solar Farms?

Several foundation types are used for solar farms in Australia. The most common include helical piles, ground screws (which are similar to helical piles but often have a continuous screw thread), driven steel posts (like I-beams), and traditional cast-in-place concrete piers or ballasts. The choice depends on factors like soil conditions, topography, environmental constraints, and project economics.

How Deep Should a Foundation Be for a Solar Panel?

The depth of a helical pile foundation for a solar panel is not a standard dimension. It is determined by the site-specific geotechnical conditions. The pile must be installed deep enough to engage a soil stratum that can support the design loads, particularly the critical wind uplift forces. This depth typically ranges from 1.5 metres to over 5 metres, depending on the soil profile. The final depth for each pile is confirmed when the target installation torque is reached.

Need a quote or more info? Start here.

Contact Us

info@helicalpilesaustralia.com.au

+61 2 7251 9258

Mon–Fri, 8:00am–5:00pm AEST

Built for complexity.

Engineered for certainty.

A trusted partner for large-scale energy and infrastructure projects where precision isn’t optional, it’s mandatory

© 2025 Helical Piles Australia. All rights reserved.

Privacy Policy

Contact Us

info@helicalpilesaustralia.com.au

+61 2 7251 9258

Mon – Fri, 8:00am – 5:00pm AEST

Location

Ground Floor 3, 189 Kent St

Sydney, NSW 2000