ARTICLE

Engineer's Guide to Helical Piles for Solar Farms in Australia

Australia’s large-scale solar sector requires foundation solutions that are not just robust but also efficient and adaptable. As engineers seek to optimise project timelines and budgets, helical piles, also known as screw piles, have emerged as a superior alternative to conventional concrete footings.

They provide a reliable engineering solution that meets the demands of rapid deployment across the continent’s diverse and often challenging landscapes. This guide provides a technical overview of the benefits and design considerations of using helical piles for solar farm applications, specifically for engineers operating within Australia.

Summary

- Rapid Installation: Helical piles significantly reduce construction timelines for solar projects compared to traditional concrete foundations.

- Versatility: Ideal for a wide range of Australian soil types, including reactive clays, sandy soils, and remote locations.

- Cost-Effective: Lower costs associated with labour, machinery, and material, with no spoil removal required.

- Minimal Impact: Vibration-free installation preserves the site’s integrity and reduces environmental disturbance.

- Immediate Loading: Piles can be loaded immediately after installation, accelerating the solar panel mounting process.

- Durability: Galvanised steel offers long-term performance and resistance to Australian climatic conditions.

Technical Advantages of Helical Piles in Solar Applications

Installation Speed and Project Acceleration

The most significant advantage of helical piles is the speed of installation. Unlike traditional concrete foundations that require excavation, formwork, steel fixing, pouring, and curing, helical pile installation is a single, streamlined process.

A pile can be installed in a matter of minutes. This eliminates the lengthy curing period associated with concrete, which can be a major bottleneck in project scheduling. Once a helical pile is installed to the specified torque, it can be loaded immediately.

This allows solar racking and panel installation to commence without delay, compressing the overall construction timeline and leading to faster project commissioning and revenue generation.

Performance Across Diverse Australian Soil Conditions

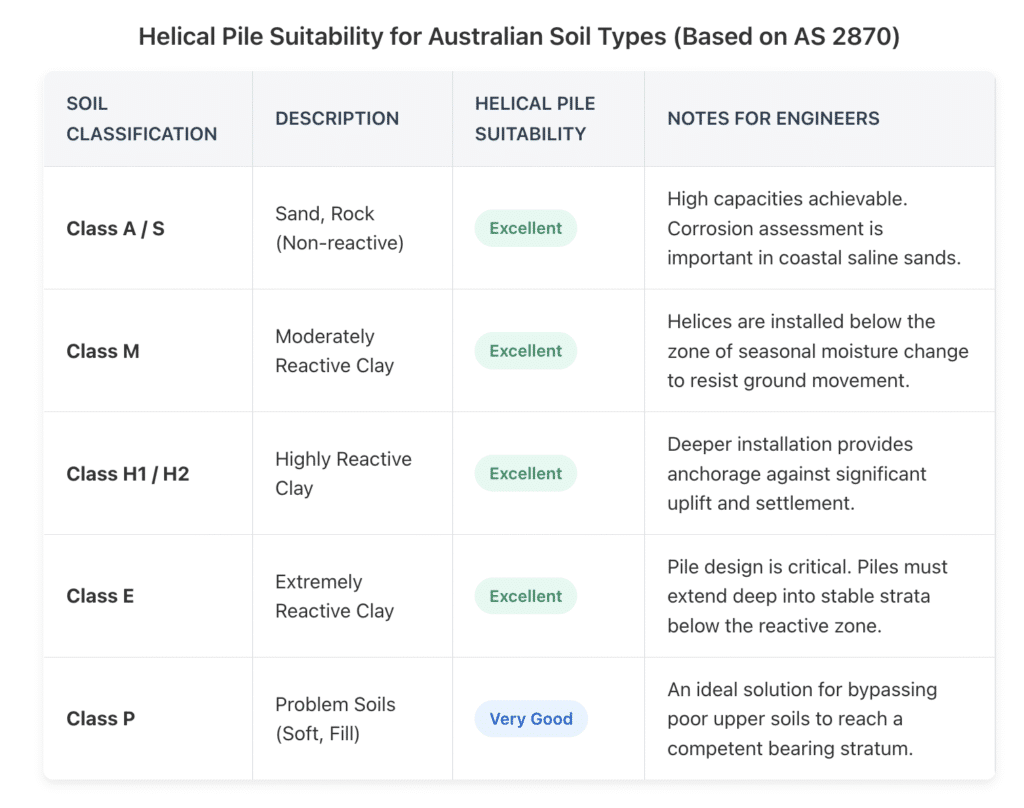

Australia’s geology is incredibly varied, from the highly reactive clays in Victoria and South Australia to the soft, sandy soils of coastal Western Australia and the hard, dry ground of the outback. Helical piles are exceptionally versatile and can be engineered for predictable performance in nearly all of these conditions.

The pile’s design, including the number and diameter of helices, is tailored to the specific geotechnical properties of a site. In soft or loose soils, larger helices provide a greater bearing area. In contrast, for dense soils, a slimmer profile can be used to penetrate the ground effectively.

This adaptability makes them a reliable ground mount solar foundation system across the country.

Minimal Site Disturbance and Environmental Benefits

The installation of helical piles has a low environmental impact. The process is vibration-free, which is a key consideration on sites adjacent to sensitive infrastructure or natural habitats.

The equipment used, typically an excavator with a hydraulic drive head, is standard on most construction sites and has a smaller footprint than large piling rigs or a fleet of concrete trucks.

A major benefit is the elimination of excavated spoil. With no digging required, there is no excess soil to be transported and disposed of, saving on costs and reducing the project’s carbon footprint. This makes helical piles an excellent choice for projects with strict environmental controls.

Design and Engineering Considerations for Solar Helical Piles

Understanding Load Capacities: Tension, Compression, and Lateral Forces

The design of a solar array foundation must account for three primary forces: compression (downward), tension (uplift), and lateral (shear). Solar arrays, with their large surface areas, are particularly susceptible to wind-induced uplift forces.

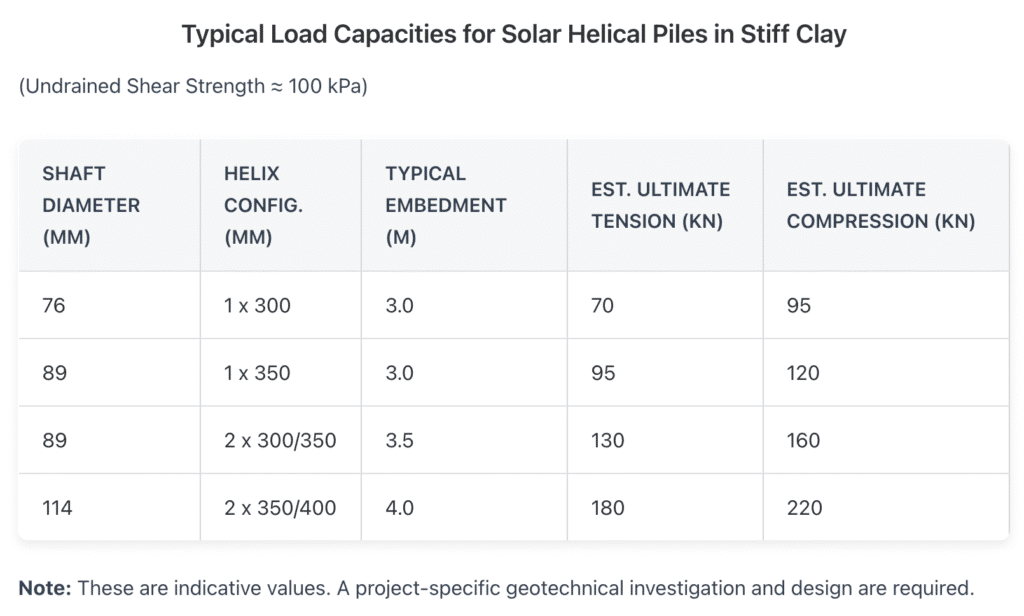

Helical piles are uniquely suited to resist tension loads due to their helical plates, which act like anchors in the soil. The helical pile load capacity is determined through geotechnical analysis and is verified during installation.

A direct empirical relationship exists between the torque required to install the pile and its ultimate holding capacity. This allows for real-time quality control on every pile installed, providing engineers with a high degree of confidence in the foundation’s performance.

On Helical Piles for Australian Solar Projects

For engineers designing solar farms in Australia, helical piles offer a technically sound, efficient, and cost-effective foundation system. Their performance across the continent’s diverse soil conditions, combined with the significant time savings during construction, presents a clear advantage.

The ability to verify the capacity of each pile during installation provides unparalleled quality assurance. By minimising site disturbance and logistical complexity, helical piles represent a modern engineering solution that aligns perfectly with the goals of sustainable and rapid energy infrastructure development.

Frequently Asked Questions About Helical Piles for Solar

How Long Do Helical Piles Last?

With a proper geotechnical design and standard hot-dip galvanisation, helical piles are engineered to meet the specific design life of a project. For a typical solar farm, this means they are designed to last 25-50 years, well beyond the operational life of the solar panels themselves, even when installed in Australia’s varied and sometimes harsh soil environments.

Are Helical Piles Cheaper Than Concrete?

While the upfront material cost per pile can sometimes be comparable to a concrete footing, the total installed cost of helical piles is generally lower. The savings come from dramatically reduced labour costs, faster installation times, no need for excavation or spoil removal, and fewer weather-related delays. This makes them a more economical choice for the entire project lifecycle.

What Are the Disadvantages of Helical Piles?

The primary limitation of helical piles is in ground with extensive rock or dense layers of boulders and cobbles, which can cause the pile to refuse before reaching its target depth or torque. This is precisely why a thorough geotechnical investigation is a mandatory first step to identify such obstructions and confirm the site’s suitability.

What Is the Load Capacity of a Helical Pile?

The helical pile load capacity is not a fixed value; it is custom-engineered for each specific project and location. It is determined by the pile’s mechanical properties (shaft size, helix configuration) and, most importantly, the strength of the soil it is installed in. Capacities are calculated to safely handle all design loads, including high wind uplift on solar arrays.

Can You Use Screw Piles for Solar Panels?

Yes, absolutely. The terms “screw piles” and “helical piles” are used interchangeably in the industry to describe the same foundation system. They are an excellent and widely used foundation solution for ground-mounted solar panels, from small residential arrays to large-scale, utility-grade solar farms.

What Are the Best Foundations for Solar Panels?

While several foundation options exist, helical piles are often considered the best all-around solution for ground-mounted solar panels in Australia. This is due to their ideal combination of rapid installation, minimal environmental impact, immediate load-bearing capability, and high performance across the vast majority of Australian soil conditions.

Need a quote or more info? Start here.

Contact Us

info@helicalpilesaustralia.com.au

+61 2 7251 9258

Mon–Fri, 8:00am–5:00pm AEST

Built for complexity.

Engineered for certainty.

A trusted partner for large-scale energy and infrastructure projects where precision isn’t optional, it’s mandatory

© 2025 Helical Piles Australia. All rights reserved.

Privacy Policy

Contact Us

info@helicalpilesaustralia.com.au

+61 2 7251 9258

Mon – Fri, 8:00am – 5:00pm AEST

Location

Ground Floor 3, 189 Kent St

Sydney, NSW 2000