ARTICLE

Load-Bearing Capacity of Helical Piles in Australia

Determining the helical pier load capacity is a precise engineering process, not guesswork. It involves a combination of theoretical analysis, real-time data from the installation, and sometimes, physical testing. The initial design is based on a geotechnical investigation of the site.

During installation, the torque required to screw the pile into the ground provides an immediate and reliable indication of the capacity being achieved. For critical projects, a physical load test offers final verification.

This comprehensive approach ensures that the foundation is perfectly suited to the ground conditions and the structural requirements, involving a qualified geotechnical engineer and specialist installers.

Summary

- What It Is: The load-bearing capacity of a helical pile is the maximum load it can support without failure or excessive settlement.

- How It’s Determined: Capacity is predicted using torque correlation during installation and verified through geotechnical analysis and screw pile testing.

- Key Factors: Soil type, pile design (diameter, helix configuration), and installation depth are the most significant factors influencing the screw pile load capacity.

- Australian Context: All design and installation must comply with Australian standards, specifically AS 2159-2009 for piling design and installation.

- Why It Matters: Correctly determining capacity ensures the long-term safety and stability of your structure’s foundation.

Key Factors Influencing Helical Pile Capacity

Several interacting factors determine the final load-bearing capacity of helical piles. While the steel pile itself is incredibly strong, its performance is ultimately dictated by how it interacts with the ground it is installed in.

The Role of Soil Conditions

The ground is the most important factor. A helical pile works by transferring the structural load from the building through the pile shaft and into the surrounding soil via its helical plates.

The properties of the soil conditions therefore dictate the pile’s capacity. Key soil characteristics that engineers analyse include its density, cohesion (how well it sticks together), and friction angle.

The goal is always to install the pile deep enough to reach a stable, load-bearing soil layer, bypassing any weak or unstable soils near the surface.

Helical Pile Design and Specifications

The physical design of the helical pile itself plays a significant role in its capacity. The pile’s diameter, the number of helical plates, the diameter of those plates, and their spacing are all engineered for specific outcomes.

A larger shaft diameter provides greater resistance against bending. Increasing the number or size of the helical plates allows the pile to engage a larger volume of soil, which directly increases its bearing capacity.

These components are specified by an engineer based on the soil data and the loads of the structure. The high-strength galvanised steel used also ensures durability against corrosion.

Installation Process and Equipment

The quality of the installation is just as important as the pile design and soil quality. Helical piles must be installed using specialised hydraulic-driven equipment that provides controlled torque and downward pressure.

This ensures the pile advances into the ground smoothly without disturbing the surrounding soil structure. An experienced installation crew ensures the pile is installed perfectly straight and to the correct depth and final torque.

Any deviation from the engineered plan, such as misalignment, can compromise the pile’s intended load-bearing capacity.

Understanding Torque and Its Correlation to Capacity

One of the unique advantages of helical piles is the ability to verify their capacity during installation. This is done through torque correlation.

In simple terms, torque is the amount of rotational force needed to turn the pile into the ground. As the pile advances into denser, stronger soil, more force is required to turn it, and the measured torque value increases.

There is a direct and proven relationship between this final installation torque and the pile’s ultimate capacity.

Engineers use a well-established formula (Capacity = Kt x T), where ‘T’ is the final installation torque and ‘Kt’ is an empirical torque factor that varies with the pile’s shaft size.

This method provides a reliable, real-time confirmation that the pile has reached the required depth and achieved the designed screw pile load capacity, offering peace of mind on site.

| Feature | Compression Load (Downward Force) | Tension Load (Uplift/Upward Force) |

|---|---|---|

| Description | A downward force that pushes the pile into the ground, typically from the weight of a structure. | An upward force that attempts to pull the pile out of the ground. |

| Mechanism of Resistance | The load is transferred through the steel shaft to the helical plates, which act as end-bearings against the soil. Additional resistance is provided by skin friction along the pile shaft. | The helical plates act like anchors or the threads of a screw in timber. The soil above the plates provides resistance, preventing the pile from being extracted. |

| Primary Use | To provide primary foundation support and prevent settlement. | To resist uplift forces from wind, hydrostatic pressure, or overturning moments. |

| Common Australian Applications |

|

|

| Engineering Consideration | The design focuses on ensuring the pile reaches a soil layer with adequate end-bearing capacity to support the structural load without settling. | The design focuses on the size and number of helices to ensure sufficient soil is engaged above the plates to resist the calculated uplift force. |

The Importance of a Geotechnical Report

A geotechnical report is the essential starting point for any professional foundation design. This report, prepared by a geotechnical engineer, details the findings from a site-specific soil investigation.

It involves drilling boreholes, collecting soil samples, and conducting laboratory tests to understand the ground beneath a property.

This report provides the critical data needed for designing reliable foundation solutions. It identifies the different soil layers, their strength, composition, density, and the location of the water table.

With this information, an engineer can accurately predict the required depth for the helical piles, select the appropriate pile configuration, and calculate the expected load-bearing capacity of helical piles for that specific site. Proceeding without this report means designing a foundation blindly.

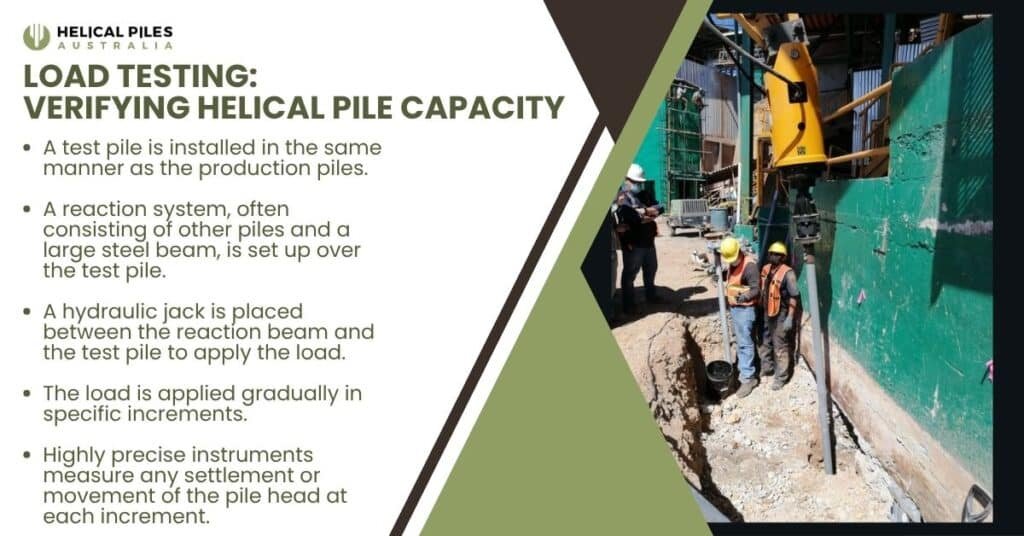

Load Testing: Verifying Helical Pile Capacity

While torque correlation provides excellent real-time data, physical screw pile testing offers definitive proof of a pile’s performance.

A load test involves applying a measured physical load to an installed pile to see how it behaves. This is the most accurate way to verify the helical pier load capacity and is often a mandatory requirement for large commercial or public infrastructure projects in Australia.

The process generally follows these steps:

- A test pile is installed in the same manner as the production piles.

- A reaction system, often consisting of other piles and a large steel beam, is set up over the test pile.

- A hydraulic jack is placed between the reaction beam and the test pile to apply the load.

- The load is applied gradually in specific increments.

- Highly precise instruments measure any settlement or movement of the pile head at each increment.

The results confirm that the pile can support the design load without excessive movement, verifying the engineering calculations and providing ultimate assurance.

Helical Pile Capacity in Different Australian Soil Types

Australia’s diverse geology presents various challenges for foundations. Helical piles are versatile enough to provide reliable support across these different soil conditions.

Reactive Clays

Found extensively across regions like Adelaide, Melbourne, and Western Sydney, reactive clays shrink when dry and swell when wet.

This constant movement can cause significant damage to traditional shallow foundations. Helical piles solve this problem by being installed deep into the ground, past the reactive clay zone, anchoring into a stable soil layer below.

This ensures the foundation remains unaffected by seasonal moisture changes at the surface.

Sandy and Silty Soils

In the sandy and silty soils common to coastal areas like Perth and Brisbane, helical pile capacity is achieved through soil friction and end-bearing on the helical plates.

As the pile is screwed into the ground, the helices compact the surrounding sand, increasing its density and bearing capacity. The pile’s depth and helix configuration are engineered to maximise this effect, providing excellent stability even in loose or non-cohesive soils.

Rock and Hard Ground

When building on sites with shallow bedrock, helical piles can be used to found directly on the rock for extremely high capacity. In these situations, the pile is advanced until the helical plates make contact with the rock surface, a process known as “seating” on the rock.

The installation torque will increase dramatically, indicating that a solid base has been reached. Specialised pile designs can even be used to penetrate softer or fractured rock layers.

Australian Standards for Helical Pile Design

The design, installation, and testing of helical piles in Australia are governed by strict engineering codes to ensure safety and quality. The primary standard is AS 2159-2009 (Piling – Design and installation).

This comprehensive document outlines the minimum requirements that engineers and installers must follow.

Adherence to Australian standards is not optional; it is a legal and professional requirement. AS 2159 covers all aspects of the process, including how to interpret a geotechnical report, methods for calculating pile capacity, required factor of safety margins, and the procedures for conducting load testing.

By working with a provider who strictly adheres to these standards, you can be confident that your foundation is designed and installed correctly and safely.

Compression vs. Tension Loads on Helical Piles

Helical piles are exceptionally effective at resisting both downward and upward forces, known as compression and tension loads.

Compression is the standard downward pressure a foundation experiences from the weight of a building. The helical plates provide a large surface area to bear against the soil, preventing the structure from sinking. This is the primary function for most building foundations, extensions, and deck footings.

Tension, or uplift, is an upward pulling force. This can be caused by wind trying to lift a structure, or by buoyant forces from groundwater.

The helical plates act like anchors, holding the pile firmly in the ground and preventing it from being pulled out. This makes them ideal for securing solar panel arrays, communication towers, or structures in flood-prone areas across Australia.

The load-bearing capacity of helical piles is not a simple figure but the result of a thorough engineering process. It relies on a deep understanding of the site’s unique soil conditions, a proper pile design, and a quality-controlled installation.

The unique ability to measure capacity in real-time using torque correlation makes helical piles a predictable and highly reliable system. When designed and installed according to Australian standards, these foundation solutions provide a secure and durable base for structures all across the country.

Always consult with a qualified specialist to ensure the correct capacity for your project’s specific needs.

Frequently Asked Questions About the Load-Bearing Capacity of Helical Piles

How Much Weight Can a Helical Pile Hold?

The weight a single helical pile can hold varies significantly based on the soil conditions and the pile’s design. A small-diameter pile in soft clay might support a few tonnes, while a large-diameter pile installed deep into dense sand or rock could support over 100 tonnes. The capacity is engineered specifically for each project’s requirements.

How Is the Load Capacity of a Helical Pile Determined?

The load capacity is determined through a three-part process. First, a geotechnical engineer analyses a soil report to create a theoretical design. Second, during installation, the torque required to screw the pile in is monitored, providing a real-time verification of capacity. Third, for critical projects, a physical load test is performed to give absolute confirmation.

What Is the Bearing Capacity of a Screw Pile?

“Screw pile” is another common name for a helical pile in Australia. Therefore, the bearing capacity of a screw pile is determined in the exact same way. It is the maximum load the pile can support, which is dependent on the pile’s size, helix configuration, and the strength of the soil it’s installed in.

How Do You Calculate the Safe Load of a Screw Pile?

The safe load (or allowable working load) is calculated by first determining the ultimate capacity of the pile through engineering formulas and torque correlation. This ultimate capacity is then divided by a factor of safety (typically between 2.0 and 3.0, as specified in Australian standards) to arrive at the safe load that will be used in the foundation design.

Are Helical Piles As Strong As Concrete Piles?

Yes, in many applications, helical piles can be designed to support the same or even greater loads than concrete piles. Their strength comes from being installed deep into competent load-bearing soil. They offer additional advantages such as faster installation, minimal site disturbance, and immediate load-carrying ability without waiting for concrete to cure.

How Long Do Helical Piles Last?

Modern helical piles are manufactured from high-grade steel and are hot-dip galvanised for corrosion protection. In most typical soil environments, this gives them a design life of over 100 years, meeting the durability requirements for permanent structures under the Building Code of Australia.

Need a quote or more info? Start here.

Contact Us

info@helicalpilesaustralia.com.au

+61 2 7251 9258

Mon–Fri, 8:00am–5:00pm AEST

Built for complexity.

Engineered for certainty.

A trusted partner for large-scale energy and infrastructure projects where precision isn’t optional, it’s mandatory

© 2026 Helical Piles Australia. All rights reserved.

Privacy Policy

Contact Us

info@helicalpilesaustralia.com.au

+61 2 7251 9258

Mon – Fri, 8:00am – 5:00pm AEST

Location

Ground Floor 3, 189 Kent St

Sydney, NSW 2000